SANY Drag Conveyors – Built for New Zealand’s Toughest Underground Conditions

SANY’s advanced drag conveyor solutions are purpose built for the demands of underground mining. Engineered to thrive under high production and challenging geological conditions, the SANY range delivers unmatched reliability, wear resistance, and intelligent automation. With a full spectrum of models – from compact systems suited for outputs under 600,000 tonnes to heavy duty machines capable of transporting over 5 million tonnes annually – SANY drag conveyors meet the diverse requirements of New Zealand’s underground coal and minerals sector.

Backed by decades of global mining experience and advanced R&D, each conveyor is designed with modular integration, soft start technology, and self diagnostic capabilities. This ensures smoother operation, predictive maintenance, and seamless compatibility with mainstream coal cutters and hydraulic supports. SANY’s unmatched ability to supply the entire mining chain including coal cutters, hydraulic supports, and conveyors makes it a trusted one stop provider for intelligent, low labour, and high output mining systems.

SANY Drag Conveyor Range

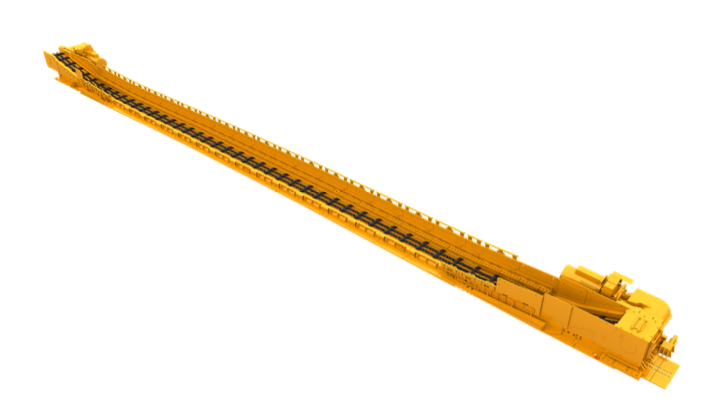

SGZ Series | Drag Conveyors

Heavy Duty Mainline Conveyors for Continuous Coal Transport

The SGZ series is SANY’s high performance mainline drag conveyor range, designed for high capacity underground mining operations. Spanning rated lengths from 130 to 380 metres, the SGZ series suits annual outputs from 600,000 tonnes to over 5 million tonnes, making it ideal for New Zealand’s diverse geological conditions.

Key Features:

Wide Capacity Range: Models from SGZ630 to SGZ1350 deliver between 450 to 4000 tonnes per hour.

Rated Lengths: From 130m (SGZ764) to 380m (SGZ1350/3×1600) depending on model and configuration.

Wear Resistance Built In: Uses NM400, JFE, Hardox, and composite wear plates for increased service life.

Smart Operations: Intelligent health diagnostics, fault prediction, chain protection, and optional autonomous controls.

Smooth Performance: Variable frequency soft start and chainless Gear-Eicotrack drive reduce mechanical stress.

Maximum Compatibility: Integrates with major coal cutter and hydraulic support brands, plus crushers and tail drives.

Long Life Design: Sprockets feature hardened surfaces to 55 HRC and wear layers up to 12 mm.

Ideal For:

Fully mechanised longwall coal mining operations looking for high capacity, long distance conveyor solutions with minimal maintenance and maximum uptime.

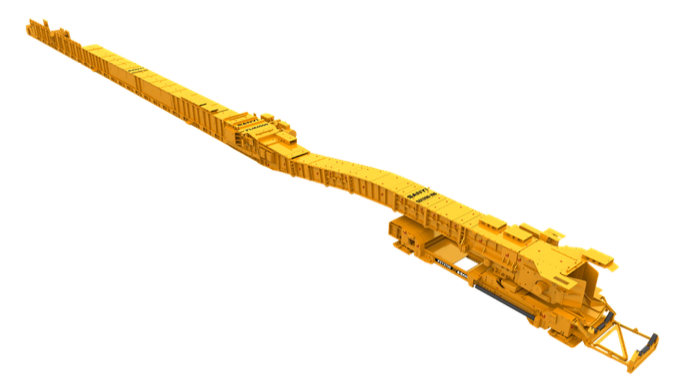

SZZ Series | Gateway Drag Conveyors

Efficient Stage Loaders for Seamless Material Transfer

The SZZ series is engineered for gateway and stage loader applications, bridging the gap between face conveyors and belt systems. With rated lengths between 45 to 350 metres, and handling capacities from 600 to 4000 tonnes per hour, these conveyors are essential for optimizing material flow in compact or transitional zones.

Key Features:

Versatile Lengths: Rated lengths from 45m (SZZ630/132) up to 350m (SZZ1200/3×1000).

Efficient Transfer: Designed to work in tandem with crushers, self-advancing belt tails, and drag conveyors.

Durable Build: Outfitted with high-strength wear materials including NM400, composite plates, and Hardox.

Smart Tensioning: Chain tensioning via brake disc or hydraulic motor with retractable tail options.

Flexible Power Options: Operates at 1140V or 3300V to suit underground site demands.

High Throughput: Delivers between 600 to 4000 tonnes per hour depending on model.

Ideal For:

Mining operations needing a compact, reliable conveyor system for transferring coal from the face to the main haulage route.